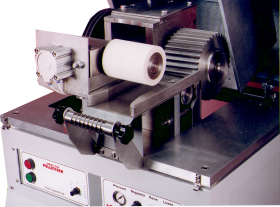

100mm feed 20 Strand dry cut Pelletizer.

Our largest overhung rotor design allows thorough clean-down of the chamber components enabling rapid process changeover when colour or polymer grade changes are required. Replacement of feed rolls and rotor can be achieved without removing bearings. This machine can be offered as single drive with change gears to give a continuous precise cut pellet or dual drive allowing the pellet length to be changed electronically ideal for customers who wish to cut both standard and micro pellets on a regular basis.

Designed for colour masterbatch production

The easy clean down and quick maintenance make the 900-4 ideal for colour changes the machine can be cleaned quickly between colour changeovers the machine is designed for fast removal of wearable parts,

Cutting soft materials

The 900-4 has a straight feed table which does not allow the strands to be bent towards the cutter, this is essential for the production of soft materials. The machine is also used for food grade applications for cutting extremely soft materials.

Dual drive option

The 900-4 Pelletizer can be supplied as single drive with a set pellet length or dual drive the dual drive option allows the operator to change pellet lengths during production. Once the desired pellet length is selected the line speed can be adjusted and the pellet length will remain the same throughout the line speed range.

Feed rolls and rotor removal

The overhung design of the machine allows the operator to remove the feed rolls and rotor from the shafts this can be achieved without the need of bearing removal.

Upper feed roll driven as standard

The upper feed roll is driven to allow maximum strand traction with special deep tooth gears this gear arrangement does not require any lubrication.

Strand Cutter and bed knife

The machine can be supplied with various cutter materials to suit any product; the bed knife is solid carbide as standard the bed knife has four usable edges.

Built to your requirements

Our 900-4 is manufactured to suit your requirements, discharge chutes can be manufactured to suit any sieve unit or collection vessel, side steps and front steps are optional extras for easy maintenance. Pelletizer controls can be positioned on the enclosure or the front of the machine, we will send you a drawing to approve and you can request modifications to suit your extrusion line requirements.

Safe no tool access

A solenoid locking safety switch is fitted to the main hood and discharge chute the switches locks the hood and discharge chute until the machine has come to a complete standstill. Once the machine has stopped the hood can be opened and the chute can be removed for easy cleaning.

Integrated sieve unit

The 900-4 Pelletizer can be fitted with a sieve unit the sieve can be fitted within the base of the machine to prevent any unwanted longs or fines.

Throughput and power

Model Feed width Strands Kg/hr SG 1.05 KW RATING

900-4 100mm 20 710 4 Kw with gears train

900-4DD 100mm 20 710 4 Kw Rotor 1.5Kw Feed rolls

Throughput shown is based on machine running at 80M per minute with 20 strands of SG1.05 the material specific gravity significantly changes the throughput of the machine. Please send us your requirements and we will work out your exact throughput.

Voltage

380/415v 3phase 50/60Hz

Complete extrusion line downstream equipment

The 900-4 can be supplied as a complete line comprising of cooling bath, Airknife and Sieve unit

Cooling bath

The cooling bath for the 900-4 is 300mm wide x 250mm deep and 3 meters long but we can manufacture to your dimensions, the cooling bath can be fitted with a plate heat exchanger and re-circulating system or a simple motorized valve to allow cool water into the bath.

Suction Airknife for strand drying

Our 800-150 suction dryer is a compact suction dryer which can be used to dry the strands prior to cutting this can be used as part of the complete extrusion line please see our ancilarry page for more details.