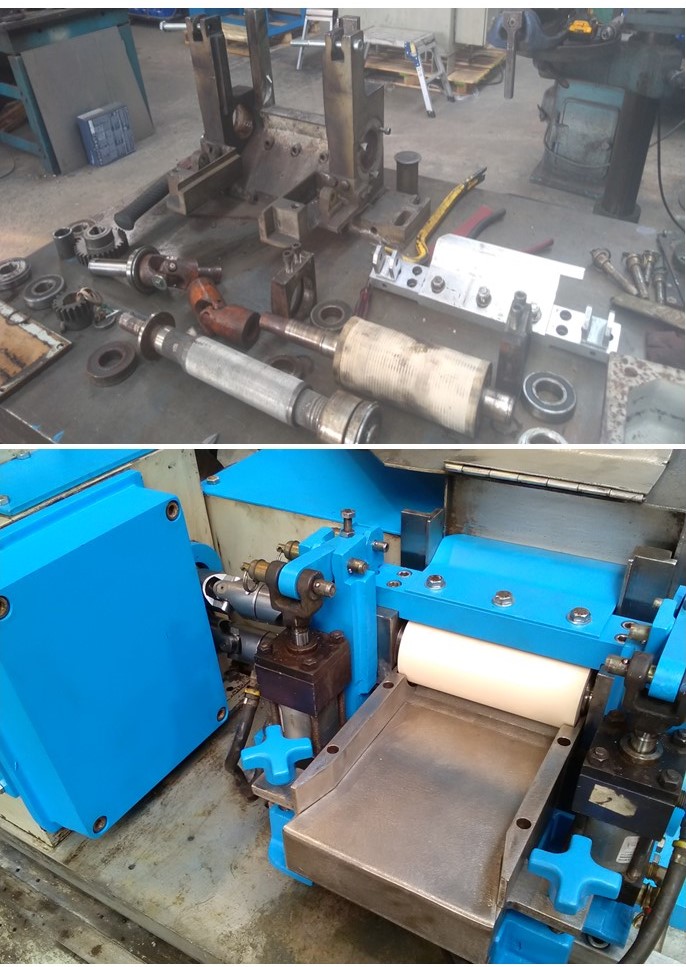

Cumberland 6” Quietizer Pelletizer repair work

After a request from one of our customers we have repaired a Cumberland 6 inch machine, the machine had broken universal joints and a damaged gear box this machine has been fixed to the customers requirements. A Full refurbishment was not required the customer just wanted the machine to be repaired to a good working condition.

Work carried out

- Remove 16 rotor bolt on blades, re-sharpen blades and re-assemble, set working clearance to bed knife.

- Remove all material contacting parts and deep clean.

- Re-spray the chambers non-contacting parts.

- Clean brass links pins.

- Remove upper feed roll, strip and recover roller with Hypalon.

- Reset upper feed roll nip distance to grip 3mm strand.

- Manufacture of new stainless steel bearing spacers on upper feed roll shaft.

- Remove feed roll bearings and replace with new.

- Strip down fabricated gear box, remove bearings, shafts and gears.

- Remove old grease from gear box.

- Manufacture new gear box drive shafts.

- Supply of new universal joints and stub shafts to allow easy removal in future.

- Fitting of new gear box bearings and circlips.

- Rebuild gear box with new drive shafts and pack with new high temperature grease

- Existing gears refitted after inspection.

- Fit new timing belt.

If you have any machines that require a repair or a full refurbishment please get in touch we can fix any make or model.